I. Introduction

Metal sheet fabrication plays a pivotal role in industry manufacture and productivity.

The metal sheet features strong versatility, forming products of various types, sizes, and shapes.

Also, it has exceptional strength, durability, and mechanical function, making it an ideal choice for applications that require solidness and a long life span.

Besides, metalworking provides the approach to producing critical structural and functional components across industries.

Through continuous innovation and breakthroughs, the metal sheet has significantly contributed to sustainable development by promoting the recycle and reuse.

In the machinery manufacturing industry, components forming is interconnected, such as casting forming, machining forming, power press forming, and press brake forming.

The two most common types in the stamping industry are compression molding and bending molding.

In manufacturing, mastering the advantages and disadvantages of each molding method helps divide the process route and prepare for the pre-production period.

This method can analyze each material's forming strategy, saving manufacturing time and productivity costs.

Here is the comparison between the power press and press brake.

II. Overview of Power Press

Definition

A power press is a press machine that can be applied to cut, punch, and mix various shapes that any metal material requires.

The energy resource of the power press regenerates from the engine of the system.

It contains different kinds of mechanical types. The power press converts rotational force into translational force.

The speed of these power presses is higher. The correct stroke range plays an essential role in power press when manufacturing.

Working Principle

The power press produces power by mechanical method.

The main principle of the power press is its motor flywheel and clutch drives gear.

The motor is the central system of the power press. The flywheel transforms the power energy into a power press.

The higher the flywheel and the level of principle is higher.

All the power components are connected, thus high speed and productivity can be generated.

In a nutshell, the application of the power press has been restricted.

Types

CÂ Frame

The CÂ type is similar to the CÂ shape, which aims to offer ground space for workers to the maximum, making the workers can move freely in the working spot.

Besides, the power press can offer additional functions such as wheel stands and gauges, often used for straightening, drawing, and assembly work.

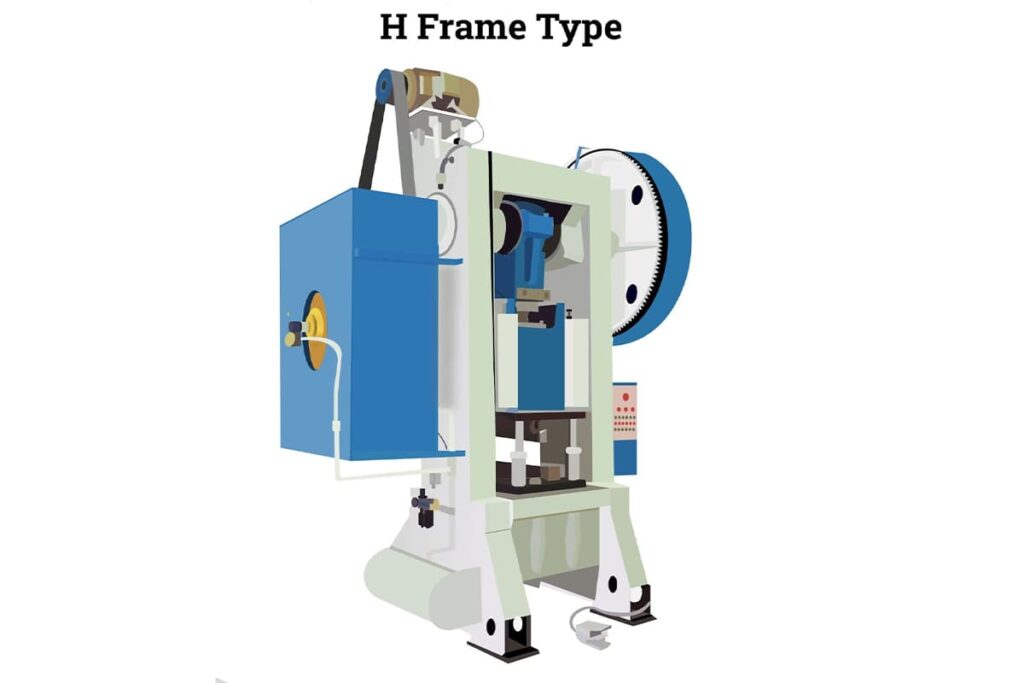

H Frame or Straight Frame

Box H-shaped design offers stronger solidness, zero deflection, lasting stability, and precise task operation.

The frame has four box-shaped four-box struts, which can be only operated in front of the power press.

H-shaped frame design can improve the blade lifespan and working accuracy, which is more expensive than the C frame power press and ring frame power press.

Hybrid Frame or Ring Frame

A hybrid frame is a mixed combination of an H frame and a C frame. In this design, the C frame offers support in the front. The opening size increases the rigidness and makes it anti-deflection. H frame design can improve the blade lifespan and workpiece accuracy.

H Frames/Straight Side Frames with Tie Rods

There are also box post frames, but the main frame is divided into four parts: pillar 1, pillar 2, crowning, base, and bed. All these four parts are equipped with hydraulic tie rods. All the power generated in the process of stroke makes the frame very solid, safe, precise, and with no deflection. Usually, these frames are used for heavy metal sheet forming and are utilized with progressive tools.

Advantages and Disadvantages

Advantages:

Simple operation: the components of the power press are interconnected. Thus, the requirement for a power press operation is easy, and the operation cost is low.

High speed: power press is a high-speed machine that boosts high productivity because of speed.

No leaks: the power press does not contain hydraulic oil. Thus, there is no leaking problem in the power press.

Disadvantages:

Fixed stroke limitation: the components of the power press are interconnected, thus creating a fixed stroke limitation, which is not applicable for those applications requiring variable stroke lengths.

high-cost maintenance: the components of the power press is very expensive.

Components

Any power press is composed of a frame, a bed or bolster plate, and a reciprocating member called a ram or slide which exerts pressure on the workpiece by special tools installed on the ram and bed.

Usually, the working space between the bed and the ram is supported by the frame.

III. Understanding Press Brake

Definition

The press brake is a machine used for bending sheet metal.

It forms expected bending by clamping the workpiece between the corresponding top punch and bottom die.

Usually, the side of the press brake forms two pieces C shaped frames, which can be connected to the bottom workbench and top beam.

The bottom tooling is installed on the workbench, and the top tooling is installed on the top beam.

Working Principle

The basic working principle of the press brake is to move the ram using a power device.

The upper and lower tooling can then bend the sheet metal into different profiles according to the preset bending angle.

Types

Mechanical Press Brake

The traditional form of press brake in the industry is the mechanical press brake. It operates using a mechanical friction clutch operated by a mechanical foot pedal or pedal.

The mechanical clutch enables operators to control the mechanical path by mechanically clicking and slipping the clutch.

The clutch engages a flywheel operated by an electric motor, powering a crank mechanism that moves the plunger vertically to provide efficient metal bending applications.

It has different sizes, ranging from smaller units with a few square inches of work area to large machines with tens of square feet square.

Thus it can be applied in various aspects, from producing small end-of-line parts to large truck frames.

Hydraulic Press brake

The hydraulic press brake is widely applied in the current industry. It is operated by two hydraulic cylinders simultaneously, thus can be used in industry high efficient, fast metal bending applications.

The custom hydraulic press brake is the most popular type in the industry, which are highly efficient, solid, and precise, and designed according to the customers’ requirements. Thus the machine can be more effective to meet the industry’s needs and achieve faster and high-quality production.

Compared with mechanical flywheel driving press brakes, the hydraulic press brake can produce high-quality products. It is also very safe. Its punch movement can be stopped whenever you want. The hydraulic press brake can be used to various metal forming and bending through the correct type of tooling design, generating the custom shape of metal components.

CNC Press Brakes

The CNC press brake features high custom and accuracy, which uses computer technology y to improve efficiency and control precision.

Skilled operators can input the data like bending angle, sheet thickness, and width into the controller to control the controller, then deal with others.

Advantages and Disadvantages

Advantages:

More flexible: unlike other machines, the press brake is used to bend a small area to a large metal, which is applicable for any size of sheet metal.

Reduce material waste: unlike other equipment requiring various materials, this machine can improve high-end precision and accuracy. This means less material waste.

Low cost: the tooling used in the press brake is low cost and has a long lifespan.

Easy to operate: press brake is one of the easiest devices which does not need highly skilled operators.

Improved safety: modern press brake adopts many protective measures, such as laser sensor. When the operator is hurt, the laser sensor is about to stop the operation.

Disadvantages:

Space requirement: press brake has a large size, thus you must spare a lot of workshop area for the machine.

Noise: a press brake is a machine that produces noises during operation. Thus operators must wear eye-protective devices. Besides, it can rouse vibration on the work spot.

Maintenance: like an industry device, the press brake needs regular maintenance. These machines may fail when there is no proper maintenance cycle.

Training: though the press brake does not need skills possessed by other metal fabrication machines, the operators also need to accept some technology training, which may need some expenses on training fees.

Components

The main parts of the press brake include the workbench, ram, punch (the top die), and die (the bottom tool).

IV. Differences between Power Press and Press Brake

Power press and press brake are two different types of machines used in metalworking and sheet metal fabrication. Here are the key differences between them:

Function

Power press: power press is also called a mechanical press, which is mainly used for simple metal forming, such as punching, blanking, embossing, bending, and shearing. It produces force by ram downtown movement.

Press brake: it is specialized and designed for metal sheet bending and forming. It uses punch and dies to produce precise bending and folding. It needs professional operators due to its operating complexity.

Operation

Power press: it is usually operated by a foot Pedal and electricity control system. It has many tooling choices to connect to the ram, realizing the different metal fabrication operations. And it is operated at high speed, thus suitable for mass-scale production. It is designed for fast and repeatable tasks.

Press brake: it utilizes hydraulic or mechanical systems to operate. The operator fixes the metal sheet between the punch and die, and the machine exerts pressure to produce bending. Usually, the speed of the press brake is slow, thus it is used for complex bending projects, emphasizing accuracy and high-speed control.

Force and Precision

Power press: compared with the press brake, the power press usually can produce more large force. It aims to exert pressure on punching and shearing. It has lower accuracy compared with a press brake.

Press brake: it aims to offer accurate and correct operation bending. It can control the bending angle and realize repeatable bending results. The force produced by the press brake is usually lower than the power press.

Tooling and Setup

Power press: it features various tooling, including punch, die, and other accessories. Changing tool settings requires manual tool changes or adjustments, which can take some time.

Press brake: it also has many tooling, especially the bending punch and die designed for bending operation. Compared with the power press, the setting of press brake tooling is more faster and convenient.

Application

Power press: it can be applied for various metal fabrication applications, such as automotive parts manufacturing, metal stamping, and general sheet metal forming operations.

Press brake: it is mainly used for metal sheet fabrication, forming the bends and angles in components such as brackets, housings, and structural parts.

V. Conclusion

The press brake and power press are all valuable tools in metal fabrication, and they vary in operation, application, precision, and other aspects.

It is very important for us to choose the correct tools for specific tasks, ensuring productivity efficiency, and safety.

ADH is a company that has over 20 years of metal sheet fabrication and boosts press brakes. You can browse our products to choose the suitable machine or consult our sales to learn detailed information.

Act now and change your metal sheet industry!

Download the Infographic With High Resolution

Pressure Hydraulic Polyurethane Machine,Polyurethane Spray Foaming Machine,PU Steering Wheel Foaming Machine

Huatao Group Limited , https://www.sjzpulpmolding.com